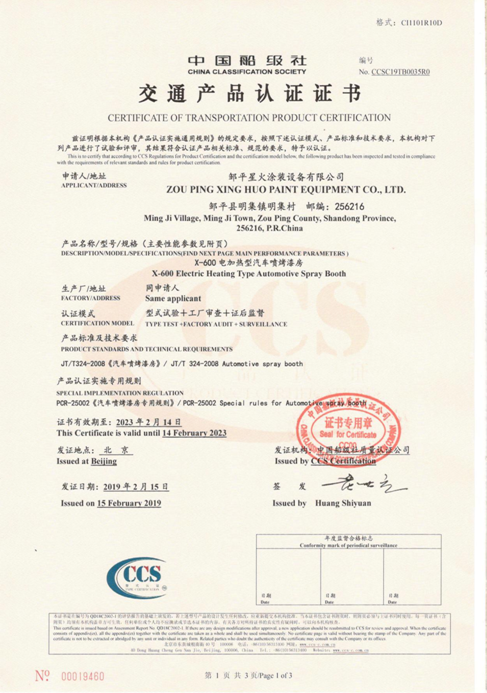

X-600 Spray Booth

X-600 spray booth main technical parameters and configuration

Key Words:

Category:

Paint Booth

E-mail:

X-600 Spray Booth

Technical Configuration

X-600 spray booth main technical parameters and configuration

1.1 Technical Data Sheet

|

No. |

Project |

Unit |

Specification |

|

|

1 |

Spray booth type |

|

Side-inlet, side-exhaust spray booth |

single station |

|

2 |

Inside diameter of the chamber |

mm |

6900×3900×2600 |

|

|

3 |

The outer diameter of the chamber |

mm |

7000×4000(+1550)×3300 |

Including 300mm base |

|

4 |

Door opening size (W×H) |

mm |

3200×2500 |

4 sheet metal gates |

|

5 |

Noise when the equipment is working |

dB |

≤85 |

|

|

6 |

Indoor illumination |

Lux |

≥800 |

|

|

7 |

Average indoor wind speed |

m/s |

≥0.3 |

|

|

8 |

Air supply filter |

|

tertiary filtration |

|

|

9 |

Paint mist treatment efficiency |

|

≥98% |

|

|

10 |

Paint temperature |

℃ |

60-80 |

|

|

10 |

Total air volume |

m³/h |

25000 |

2 sets of 4kw inlet fans |

|

11 |

Total exhaust air volume |

m³/h |

20000 |

1 set of 7.5kw exhaust fan |

1.2 Technical configuration table

|

Project name |

Configuration instructions |

|

The empty size of the chamber |

6900×3900×2600mm |

|

Chamber body dimensions |

7000×4000(+1400mm bellows+100mm isolation)×3000(+300mm base)mm |

|

1.House system |

①The wall panel of the house is made of 50mm industrial purification fireproof rock wool board, the thickness of the thermal insulation board is 50mm, the single-layer color steel plate δ0.5mm, and the rock wool bulk density is 120 kg/cubic; |

|

2.Plenum system |

①The top "T" beam is welded with 40*60mm galvanized square tube, and both ends are equipped with 2.0mm galvanized sheet folded 90°, and the connection with the paint room is lap joint; |

|

3.Gate system |

①The gate design is a folding four sheet metal tempered explosion-proof large glass door, all handmade, with built-in δ1.2mm high-strength skeleton, built-in mortise lock, and a glass observation window, which is convenient for observing the paint spraying in the room; the size of the door opening is W :3200mm×H:2500mm, the size of single door is W:800mm×H:2500mm; |

|

4.lighting device |

①The light box is folded and sprayed with high-quality δ0.8mm galvanized steel sheet, and the lighting tubes are all 16-watt Philips LED integrated tubes, with high lighting brightness; |

|

5.Air Filtration System |

①The air inlet of the fan adopts the primary filter of the special air inlet cotton; |

|

6.Fan system |

①The air supply unit uses Jiangsu YDW double-inlet fans. According to the calculation of air volume, a total of 2 sets of 4kw fans are configured for air intake. The air supply volume of each fan is 12500m³/h, and the total air supply volume is 25000m³/h. , a total of 8kw. |

|

7.Bellows system |

①The frame of the supply air box and the exhaust air box are welded by 50*50mm galvanized square tube, and the interior is equipped with a double-layer inner buckle door (sandwich) formed by bending the outer δ0.8mm galvanized sheet and the inner δ0.6mm color plate. Rock wool sound insulation), reinforced treatment, the box and the room are isolated by 100mm, reducing the noise caused by the operation of the fan during work; the box is sprayed as a whole, the appearance is beautiful and harmonious, to prevent rust. |

|

8.Heating system |

A total of 10 sets of side-by-side heating and baking lamps are configured, each set of 3kw, a total of 30kw. |

|

Diesel heating: Italian G20 diesel burner, heat exchanger made of SUS304 high-quality stainless steel. |

|

|

Natural gas heating: Italian FS20 natural gas burner, heat exchanger made of SUS304 high-quality stainless steel. |

|

|

9.Base system |

①The front and lower skirts of the house are made of δ1.2mm galvanized sheet, bent and welded, and reinforced; the other skirts are made of δ0.8mm galvanized sheet, bent and welded, and reinforced; |

|

10.Duct system |

The standard configuration is 4 sections of square air duct (1 meter per section) and other accessories. |

|

11.Electronic control system |

①Including button control, power switch, lighting switch, heating switch, fan switch, fault indicator light, emergency stop switch; |

|

12.Exhaust gas treatment system |

Equipped with two layers of activated carbon cotton and two layers of paint mist filter cotton. |

|

13.Total power consumption |

Spray paint room about 46.5kw (including 8kw blower, 7.5kw exhaust fan, 1kw lighting, 30kw heating) |

|

Optional |

①Water-based paint device: This configuration includes 1 set of water-based paint system, 2 sets of water-based paint cabinets, 2 sets of 0.55KW water-based paint fans, 2 flexible connection air outlets, and 32 water-based paint blowing nozzles; |

Belimo Electric Damper

Exhaust Fan DKF Type

Heating System Side-by-side Halogen Infrared Baking Lamp

Inlet Fan YDW Type

Intelligent Control System

Lighting System

Load-bearing Steel Grating

Paint Mist Filter Cotton

Riello G20 Diesel Burner

RielloFS20 Natural Gas Burner

Stainless Steel Heat Exchanger

X-600 Room

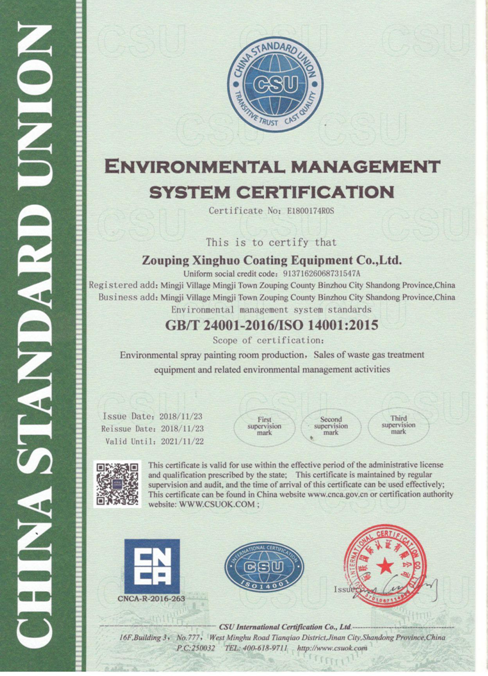

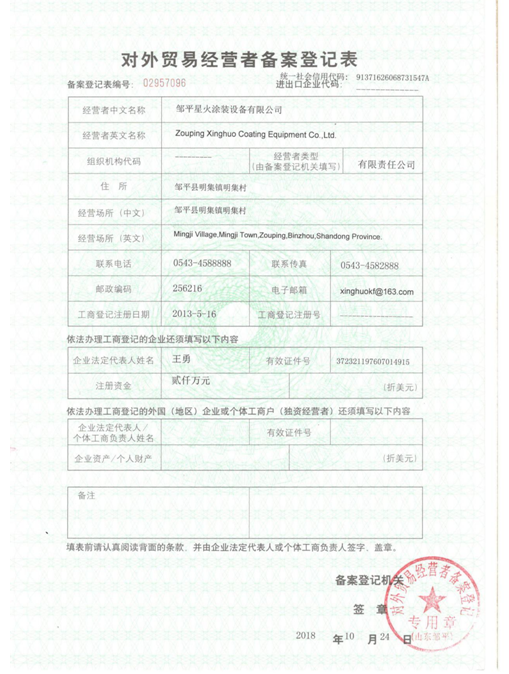

Professional Production

Quality Assurance

Customized Products

Prev

Next

Prev

X-500 Spray Booth

Next

Leave A Message